Il budget per i costumi da bagno personalizzati significa che devi trovare ogni costo. Indovini costi come costi di progettazione, campionamento e realizzazione dei prodotti. Aggiungi sempre soldi extra per le sorprese. Se salti questo, potresti avere problemi. PotrestiPaga troppo per fare il tuo costume da bagno. Potrebbe essere necessario ordinare più di quanto desideri. Potresti sentirti stressato prima che il tuo marchio diventi più grande. Fai attenzioneCattiva pianificazione e non abbastanza soldi. Potresti avere problemi con l'inventario e le stagioni lente. Potresti ottenere molti resi. I costi di spedizione possono ridurre i tuoi profitti. I tuoi obiettivi di profitto potrebbero non essere reali. Un produttore di costumi da bagno personalizzati può aiutarti a evitare questi problemi. Possono aiutarti a mantenere il tuo budget al sicuro.

Chiave da asporto

Scopri tutte leCosti nella realizzazione di costumi da bagno personalizzati. Ciò include progettazione, campionamento, materiali e spedizione. Conoscere questi costi ti aiuta a fare un buon budget.

Aggiungi sempre un importo di backup del 10-15% al tuo budget. Questo denaro extra aiuta se hai costi a sorpresa. Mantiene i tuoi profitti al sicuro e il tuo progetto in movimento.

Inizia con un piccolo ordine per provare i tuoi disegni. Questo ti aiuta a vedere se ai clienti piacciono. Abbassa il rischio e ti consente di apportare modifiche prima di spendere di più.

Parla con i produttoriPer cercare di ottenere MOQ e costi inferiori. Essere amichevoli può aiutarti a ottenere prezzi migliori e una migliore qualità.

Controlla e modifica spesso il tuo budget per commissioni nascoste o nuovi costi. Restare organizzati aiuta a non farsi sorprendere dai problemi di soldi.

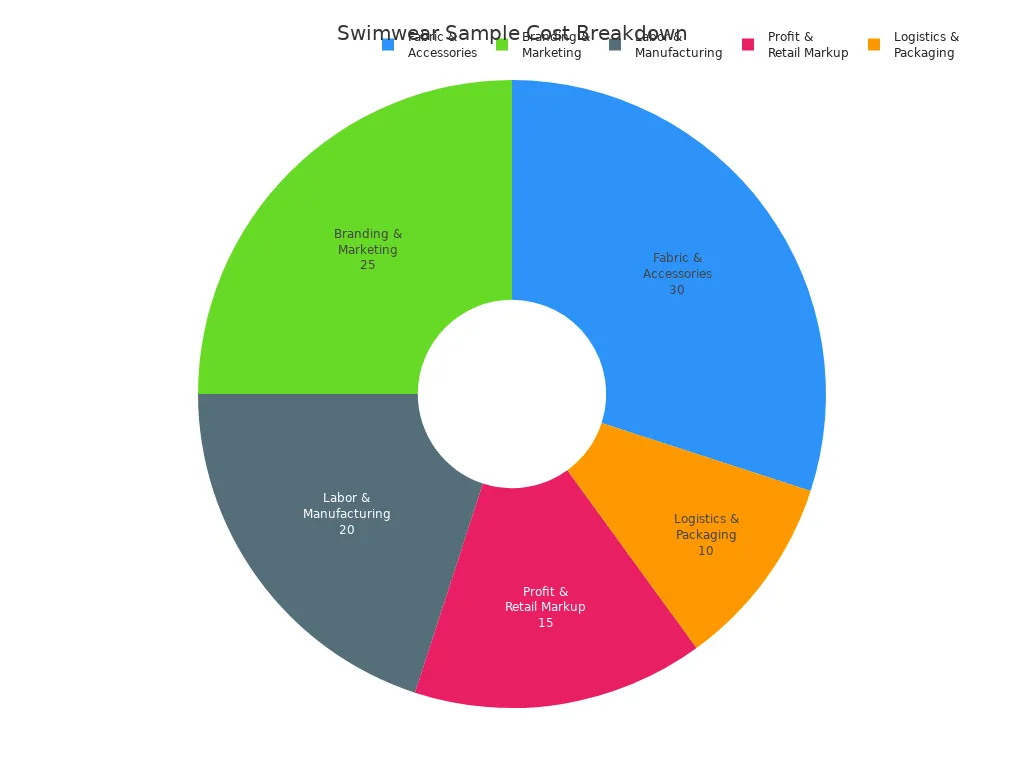

Ripartizione dei costi

Quando pianifichi la tua linea di costumi da bagno personalizzati, devi sapere dove vanno i tuoi soldi. Ogni passo nella realizzazione di costumi da bagno costa qualcosa. Diamo un'occhiata a cosa paghi per ogni parte.

Tasse di progettazione

Devi pagare per il design. Questo è quando le tue idee di costumi da bagno diventano reali. La maggior parte dei designer chiede una tassa di sviluppo. Ecco cosa potresti pagare:

Tassa di sviluppo del design personalizzato:$99(Spesso va verso il tuo grande ordine)

Costo del campione: Solitamente tre volte il prezzo all'ingrosso

Costo totale per un design personalizzato e un campione: da $50 a $100 per design (questo copre top, fondi, pezzi unici e altro)

Pianifica sempre le spese di progettazione, anche se desideri stili semplici. Queste commissioni ti aiutano a evitare errori in seguito.

Costi di campionamento

Il campionamento è importante. Devi vedere e toccare il tuo bikini prima di ordinare molti pezzi. La maggior parte delle marche ottiene diversi campioni per assicurarsi che la vestibilità e l'aspetto siano buoni.

Aspetto | Dettagli |

|---|---|

Costo iniziale del campione | |

Importanza del campionamento | Investimento critico per evitare progetti imperfetti |

Round di campionamento | I round multipli sono comuni per il perfezionamento |

Il campionamento ti aiuta a trovare i problemi in anticipo. Puoi controllare la vestibilità, il colore e il tessuto prima di acquistare molto. Le fabbriche controllano materiali, cuciture e stampe in momenti diversi. Scegliono anche costumi da bagno casuali per cercare errori.

Dovresti aggiungere il campionamento al tuo prezzo totale. Saltare questo passaggio può causare costosi errori nella produzione di massa.

Costo dei materiali

Il tessuto che scegli cambia il costo e la qualità del tuo set bikini. Ecco alcuni materiali comuni e i loro prezzi:

Tipo di materiale | Fascia di prezzo (per yard) |

|---|---|

Spandex in poliestere | |

Spandex di nylon | Da $10 a $15 |

Tessuti high-tech | Da $10 a $20 |

Le scelte materiali influenzano sia il costo che la qualità. Il tessuto che scegli può cambiare il prezzo a causa delle dimensioni dell'ordine e dei controlli di qualità. I tessuti migliori ed ecologici potrebbero aver bisogno di ordini più grandi. Questo può abbassare il costo per pezzo ma aumentare il tuo primo pagamento. La forza e il comfort del tuo costume da bagno dipendono dal tessuto. Ciò influisce su quanto sono felici i clienti e sul nome del tuo marchio.

La maggior parte dei set di bikini utilizza mezzo metro per un metro di tessuto. I costi materiali per pezzo possono essereDa $2 a $15. I buoni materiali si allungano, si asciugano velocemente e resistono al cloro e al sole. Se usi lo stesso tessuto per tutti i tuoi set di bikini, avrai meno errori e una migliore qualità.

Costo di produzione

Ora fai il tuo costume da bagno. I costi di produzione dipendono da quanti set di bikini ordini e da dove li realizzi.

Prezzo per pezzo (USD) | |

|---|---|

$20 - $30 + | |

Circa 300 unità | $9 - $20 |

Il costo del lavoro cambia per località:

Posizione | Costo del lavoro per pezzo |

|---|---|

Stati Uniti | $10 - $20 |

Oltreoceano (Cina) | $2 - $5 |

La Cina ha buoni prezzi e può fare molto. Il Portogallo è noto per l'alta qualità e metodi verdi. Il Vietnam e la Thailandia sono economici e stanno migliorando.

Devi aggiungere sia il campionamento che la produzione di massa al tuo budget. Il costo per fare costumi da bagno diminuisce man mano che ordini di più, ma il costo totale per set bikini dipende ancora dalle tue scelte.

Etichettatura e imballaggio

L'etichettatura e la confezione rendono piacevole il tuo set bikini. Puoi scegliere opzioni semplici o ecologiche.

L'etichettatura e l'imballaggio di solito costanoDa $1 a $5Per unità.

Ecco alcuni materiali di imballaggio popolari:

Tipo di materiale | Caratteristiche |

|---|---|

Kraft ecologico | Forte, durevole, ampiamente usato |

Scatole riciclate | Minimizza i rifiuti, rispettosi dell'ambiente |

Biodegradabile | Riduce l'impatto ambientale |

Rigido | Altamente protettivo, riciclabile |

Ondulato | Conveniente, facile da personalizzare |

La confezione ecologica può aumentare il prezzo totale, ma aiuta il tuo marchio a distinguersi.

Spedizione e doveri

I dazi di spedizione e importazione possono sorprenderti se non li pianifichi. Ecco cosa potresti pagare:

Valore delle merci$138,97Può avere spese di importazione di $117,64.

Le merci del valore di $47,52 potrebbero avere spese di importazione di $60,57.

Anche il metodo di spedizione è importante:

Metodo di spedizione | Tempi di consegna | Impatto sui costi |

|---|---|---|

Trasporto aereo | 3-7 giorni (internazionale) | Costi più alti, buoni per gli ordini urgenti |

Trasporto marittimo | 2-6 settimane | Più economico per la massa, ha bisogno di pianificazione |

Dovresti sempre aggiungere spedizioni e dazi al costo totale per set bikini. Il trasporto aereo è veloce ma costa di più. Il trasporto via mare è più lento ma consente di risparmiare denaro se ordini molto.

Tariffe varie

Non dimenticare i costi aggiuntivi quando inizi un marchio di costumi da bagno personalizzati. Questi possono sorprenderti se non stai attento.

Sviluppo di siti Web o piattaforme di e-commerce

Spese di branding e marketing

Anche i cambiamenti di pattern e la classificazione possono costare molto. I costi ogni anno per la classificazione del modello possono essereDa $82.500 a $98.500. Se le tue dimensioni non sono corrette, potresti sprecare tessuto, avere ritardi o ottenere resi. Questi problemi possono danneggiare il nome del tuo marchio e aumentare il prezzo totale.

Suggerimento: aggiungi sempre denaro extra nel tuo budget per le sorprese. Ciò mantiene la tua produzione e produzione sulla buona strada e protegge i tuoi profitti.

Quando si sommano tutti questi costi, si ottiene il costo totale per set bikini. Questo numero ti aiuta a impostare i prezzi e ad assicurarti che la tua attività di costumi da bagno guadagni.

Stima il tuo budget

Calcoli campione

Vuoi sapere quanti soldi hai bisogno prima di iniziare la tua linea di costumi da bagno. Antimoliamo una stima del budget campione in modo che tu possa vedere dove vanno i tuoi soldi. Questo ti aiuta a pianificare ed evitare sorprese.

Ecco una tabella che mostra quanto potresti pagare per ogni articolo:

Tipo di articolo | Fascia di prezzo |

|---|---|

In alto, in basso | $12 - $25 |

Un pezzo | $22 - $35 |

Costo del campione | 3x prezzi unitari |

Tariffe per documenti | $100 - $150 |

Dovrai anche pensare ad altri costi. Questi includono progettazione, campionamento, materiali, produzione, etichettatura, imballaggio, spedizione e dazi. Se vuoi lanciare un piccolo marchio di costumi da bagno, il tuo investimento iniziale può iniziare a partire da $5.000. Molti marchi spendono tra $5.000 e $30.000 per iniziare. Alcune boutique di fascia alta spendono oltre $100.000.

Ecco come potresti dividere il tuo budget:

Categoria di costo | Negozio su piccola scala | Operazione di medie qualità | Boutique di fascia alta |

|---|---|---|---|

Investimento iniziale | $15.000-$30.000 | $30.000-$75.000 | > $100.000 |

Assegnazione di inventario | Fino al 40% | Fino al 40% | Varia |

Allocazione marketing | Almeno il 20% | Almeno il 20% | Varia |

Dovresti mettere fino al 40% del tuo budget nell'inventario. Il marketing ha bisogno di almeno il 20%. Il resto copre la progettazione, il campionamento e altre tariffe. Se gestisci bene i tuoi soldi, potresti vedere i tuoi primi profitti in circa otto mesi.

Man mano che ordini più pezzi, il costo per unità diminuisce. Ciò accade perché distribui costi fissi su più articoli. Se ordini una quantità minima superiore, paghi meno per ogni bikini o pezzo unico. Controlla sempre i tuoi costi di produzione rispetto alla stima del budget e ai tuoi obiettivi di vendita. Questo ti aiuta a scegliere la giusta dimensione dell'ordine.

Suggerimento: inizia con un ordine più piccolo se vuoi testare i tuoi disegni. Puoi sempre aumentare il tuo ordine in seguito quando sai cosa vende meglio.

Buffer di emergenza

Non importa quanto bene pianifichi, possono apparire costi imprevisti. Potresti dover affrontare spese di spedizione extra, dazi doganali o persino modifiche nel tuo design. A volte, è necessario fissare uno schema o pagare per campioni extra. Queste cose possono sommarsi velocemente.

Una stima del budget intelligente include sempre un buffer di emergenza. La maggior parte degli esperti dice che dovresti mettere da parte il 10-15% del tuo budget totale per le sorprese. Questi soldi extra mantengono la tua attività al sicuro se qualcosa va storto.

Ecco alcuni costi imprevisti comuni:

Costo inaspettato | Descrizione |

|---|---|

Sottovalutare le spese di ristrutturazione | Potrebbe essere necessario spendere di più per il design e gli infissi dei negozi pop-up. |

Ignorare le commissioni nascoste | I dazi doganali e di spedizione possono essere più alti di quanto ti aspetti. |

Mancanza di fondi di emergenza | Se non hai soldi di backup, ritardi o problemi possono rallentare il tuo lancio di oltre il 20%. |

Nota: se salti il buffer, rischi di rimanere senza soldi. Questo può ritardare il lancio o costringerti a tagliare gli angoli.

Quando pianifichi il tuo budget, aggiungi sempre questo 10-15% in più. Ad esempio, se i costi totali sono $10.000, dovresti risparmiare $1.000 a $1.500 in più per le emergenze. Questo mantiene il tuo progetto sulla buona strada e protegge i tuoi profitti.

MOQ & Costumi da bagno personalizzati

Impatto MOQ

Quando cerchi un produttore di costumi da bagno personalizzati, sentirai parlare di "MOQ". MOQ significaQuantità di ordine minimo. Mostra quanti costumi da bagno è necessario acquistare in una sola volta. MOQ cambia quanto si paga per ogni costume da bagno.

Se ordini meno di 100 costumi da bagno, ognuno costa di più. Le fabbriche devono pagare le tasse di installazione e acquistare piccole quantità di tessuto. Questo rende ogni costume da bagno più costoso. Se ordini circa 300 costumi da bagno, ognuno costa meno. La fabbrica può distribuire i costi su più costumi da bagno, in modo da risparmiare denaro.

Ecco una tabella che mostra come MOQ cambia il tuo prezzo:

Quantità ordine | Intervallo di prezzo unitario | Spiegazione |

|---|---|---|

MOQ basso (meno di 100 unità) | $20 - $30 + | I costi sono più alti a causa di piccoli ordini e tessuto costoso |

Alto MOQ (circa 300 unità) | $9 - $20 | I costi sono inferiori perché la fabbrica condivide le commissioni di installazione e acquista tessuti all'ingrosso |

Se ordini di più, ogni costume da bagno costa meno.

Se ordini meno, ogni costume da bagno costa di più.

I piccoli ordini significano che il tessuto e la configurazione costano di più.

Se stai iniziando una linea di costumi da bagno, potresti provare prima i tuoi modelli. Alcuni produttori, come Tack Apparel, ti consentono di ordinare piccole quantità. Questo ti aiuta a provare diversi stili e tessuti senza spendere troppo. Puoi mantenere il tuo budget al sicuro ed evitare di acquistare troppi costumi da bagno.

Ordinare più costumi da bagno ti aiuta a risparmiare denaro. Quando si acquista di più, il prezzo per ogni costume da bagno scende. Questo ti aiuta a stabilire prezzi migliori e raggiungere i tuoi obiettivi di profitto.

Scelta di un produttore

Scegliere un produttore di costumi da bagno personalizzati è importante. Vuoi qualcuno che faccia buoni costumi da bagno e abbia prezzi equi. Ecco le cose da controllare:

Qualità dei materiali

Tempi di consegna

Certificazioni etiche

Opzioni di personalizzazione

Abilità del produttore e caratteristiche speciali

Cerca produttori che sappiano come fare costumi da bagno.

Controlla se hanno certificazioni come ISO 9001 o OEKO-TEX.

Scegli i produttori che possono realizzare costumi da bagno forti e di alta qualità.

Anche dove si trova la fabbrica conta. Le fabbriche in Turchia rendono veloci i buoni costumi da bagno. Il Portogallo ha a cuore l'ambiente e ha una forte attività tessile. Questi luoghi possono costare di più, ma aiutano il tuo marchio a sembrare speciale.

I buoni partenariati partono dalla ricerca e da regole chiare. Gli ordini di prova e le fabbriche in visita ti aiutano a controllare la qualità. Il produttore che scegli aiuta a costruire l'immagine del tuo marchio e la fiducia dei clienti. Se sei nuovo ai costumi da bagno, le MOQ flessibili ti aiutano a testare il mercato e controllare i costi.

Suggerimento: chiedi sempre informazioni sull'esperienza del produttore, sulle certificazioni e se possono consegnare costumi da bagno personalizzati in tempo. Questo aiuta la tua produzione a procedere senza intoppi e mantiene i tuoi prodotti di alta qualità.

Suggerimenti per il budget

Inizia in piccolo

Non è necessario ordinare subito centinaia di set bikini. Inizia con una piccola corsa. Questo ti aiuta a testare i tuoi disegni e vedere cosa piace ai tuoi clienti. Puoi controllare la qualità del tuo costume da bagno prima di spendere l'intero budget. Se inizi in piccolo, puoi modificare i prezzi e gli stili man mano che impari cosa funziona. Molti marchi iniziano con alcuni stili e colori bikini core. Ciò mantiene bassi i costi e rende l'inventario facile da gestire.

Suggerimento: segna il tuo prezzo dal 100% al 150%. Questo copre i tuoi costi e ti aiuta a realizzare un profitto. Ad esempio, se il tuo bikini costa $15, imposta il prezzo da $30 a $37,50.

Negoziare i costi

Puoi parlare con il tuo produttore per ottenere unQuantità di ordine minimo inferiore. Molte fabbriche vogliono aiutare i nuovi marchi, quindi hai delle scelte. Dì loro il tuo budget e quanti pezzi di costumi da bagno hai bisogno. Ecco alcuni modi per abbassare il costo:

Discutere le quantità minime di ordine (MOQ) con il produttore.

Ordini di pool con altri marchi per soddisfare le MOQ e risparmiare denaro.

Concentrati su alcuni stili e colori bikini per mantenere le cose semplici.

Costruisci la fiducia con il tuo produttore per offerte migliori.

Prova i modelli di preordine per ridurre il rischio di inventario.

Se costruisci un buon rapporto, potresti ottenere prezzi migliori e una qualità superiore. Fai sempre domande e condividi i tuoi obiettivi.

Piano per le tasse nascoste

Le commissioni nascoste possono sorprenderti e danneggiare il tuo budget. Potresti dimenticare le modifiche del modello, le dimensioni dei campioni extra o le spese di spedizione. Questi costi si sommano velocemente. Fai attenzioneInsidie comuni:

Sottovalutare le spese di ristrutturazione per il tuo negozio o sito web

Ignorare le tasse nascoste nella spedizione o nella dogana

Non pianificare costi aggiuntivi come i cambiamenti di modello

Puoi evitare sorprese facendo una lista di controllo. Rivedi spesso il tuo budget e aggiorna i prezzi se i tuoi costi cambiano. Ciò mantiene il tuo business bikini forte e i tuoi profitti al sicuro.

Costo per iniziare una linea di costumi da bagno

Lista di controllo del budget

Vuoi conoscere il costo reale per iniziare una linea di costumi da bagno. Una chiara lista di controllo ti aiuta a vedere ogni passo. Usa questo elenco per mantenere il tuo budget in pista ed evitare di perdere nulla di importante.

Annota le tue spese di progettazione.

Aggiungi i tuoi costi di campionamento.

Elenca il tuo tessuto e le spese materiali.

Includi il tuoCosto di produzione per ogni bikiniE un pezzo.

Contare le spese di etichettatura e imballaggio.

Stimare i dazi di spedizione e importazione.

Ricorda le spese legali, del sito Web e di marketing.

Metti da parte i soldi per cambiamenti o errori.

Suggerimento: controlla ogni articolo mentre vai. Questo ti tiene organizzato e ti aiuta a individuare eventuali costi mancanti.

Ecco una semplice tabella per aiutarti a tenere traccia delle tue spese:

Passo | Prezzo stimato |

|---|---|

Progettazione | $100 - $500 |

Campionamento | $200 - $1.000 |

Materiali | $500 - $2.000 |

Produzione | $2.000-$10.000 |

Imballaggio/etichettatura | $200 - $1.000 |

Spedizione/Dazi | $300 - $2.000 |

Altre tasse | $500 - $2.000 |

Piano finanziario

Hai bisogno di un piano forte prima del lancio. Inizia scrivendo il tuoCosti attesi e quantoVuoi guadagnare. Quando crei un piano aziendale, vedi il quadro generale. Puoi impostare il prezzo per ogni bikini e un pezzo unico. Questo ti aiuta a raggiungere i tuoi obiettivi.

Pensa alle dimensioni del tuo primo ordine. Inizierai in piccolo o diventerà grande? Il tuo piano dovrebbe mostrare quanti bikini vuoi vendere ea quale prezzo. Aggiungi il tuo costo totale per iniziare una linea di costumi da bagno. Quindi, indovina le tue vendite e il tuo profitto. Se pianifichi bene, puoi far crescere il tuo marchio ed evitare problemi di denaro.

Ricorda: un buon piano ti aiuta a gestire le sorprese e mantiene forte la tua attività di costumi da bagno.

Ora sai come budget per la tua linea di costumi da bagno. Inizia elencando ogni costo. Stimare ognuno e aggiungere un piccolo extra per le sorprese. Parla con un produttore di costumi da bagno personalizzati per ottenere numeri reali. Usa una lista di controllo o uno strumento di budget per tenere traccia delle tue spese. Rivedi il tuo budget spesso man mano che la tua attività cresce. Un'attenta pianificazione ti aiuta a evitare lo stress e raggiungere i tuoi obiettivi.

FAQ

Quanti soldi ho bisogno per iniziare una linea di costumi da bagno?

Puoi iniziare con un minimo di $5.000. La maggior parte dei marchi spende tra $5.000 e $30.000. Le linee di fascia alta potrebbero richiedere $100.000 o più. I costi dipendono dalla dimensione dell'ordine, dai materiali e dalle scelte di progettazione.

Che cosa è MOQ, e perché è importante?

MOQ significa quantità di ordine minimo. Ti dice il minor numero di costumi da bagno che devi ordinare. Le MOQ inferiori ti aiutano a testare i tuoi progetti. Le MOQ più elevate riducono il costo per pezzo.

Posso usare materiali ecologici per i miei costumi da bagno?

Sì! Molti produttori offrono tessuti riciclati o sostenibili. Questi materiali possono costare di più, ma aiutano il tuo marchio a distinguersi. Le scelte ecologiche attirano anche i clienti che si preoccupano dell'ambiente.

Come posso evitare le commissioni nascoste?

Chiedi sempre al tuo produttore un listino prezzi completo. Verifica la presenza di costi aggiuntivi come modifiche del modello, spedizione e dazi doganali. Tieni una lista di controllo in modo da non perdere nulla.

Quanto tempo ci vuole per realizzare costumi da bagno personalizzati?

La produzione richiede solitamente da 4 a 12 settimane. Il campionamento e la spedizione aggiungono più tempo. Pianifica in anticipo in modo da non perdere la data di lancio.