Un produttore di costumi da bagno personalizzati trova il prezzo all'ingrosso sommando il costo dei materiali, della manodopera e della configurazione. È necessario guardare il prezzo perché viene da ogni passo nella realizzazione del costume da bagno. Conoscere il costo dei beni fabbricati (COGM) ti aiuta a capire perché il produttore sceglie un certo prezzo. Quando guardi il prezzo all'ingrosso, puoi vedere come i margini di profitto e tutti i costi fanno il numero finale.

Chiave da asporto

Scopri quanto costa ogni parte del costume da bagno personalizzato. Le parti principali sono materiali, manodopera e consegna. Se li conosci, puoi pianificare bene il tuo budget.

La quantità minima di ordine (MOQ) cambia il prezzo. Se ordini meno, ogni pezzo costa di più. Cerca di ordinare di più per risparmiare denaro e ottenere prezzi migliori.

Usa la matematica giusta per trovare i prezzi all'ingrosso. Somma tutti i costi e il tuo margine di profitto. Questo ti aiuta a stabilire prezzi equi e fare soldi.

Scegli un produttoreGuardando alla qualità e al prezzo. Trova uno che ti dia buoni prodotti e si adatti al tuo budget.

Chiedi sempre unElenco completo dei costi. Questo ti aiuta a vedere dove vanno i tuoi soldi e mantiene i tuoi prezzi equi.

Ripartizione dei costi per produttore di costumi da bagno personalizzati

Quando lavori con un produttore di costumi da bagno personalizzati, dovresti sapere come si somma ogni costo. Il costo dei beni fabbricati (COGM) è il punto di partenza per i prezzi all'ingrosso. Ogni passo, dalla selezione del tessuto alla spedizione, cambia il prezzo e la qualità del tuo costume da bagno.

Materiali e finiture

Il tessuto è la parte principale del tuo costume da bagno. Il tipo di tessuto che scegli, come il nylon riciclato o lo spandex, cambia il prezzo e come ci si sente. Il tessuto migliore costa di più ma dura più a lungo e si sente più bello. Anche le finiture, come elastici, ganci e decorazioni, si aggiungono al costo. Se vuoi finiture speciali o ecologiche, il prezzo sarà più alto. I produttori controllano la qualità del tessuto, quanto ti serve e i prezzi di mercato per fissare i costi. I prezzi del tessuto possono cambiare, quindi dovresti controllarli spesso per mantenere i costi bassi e la qualità alta.

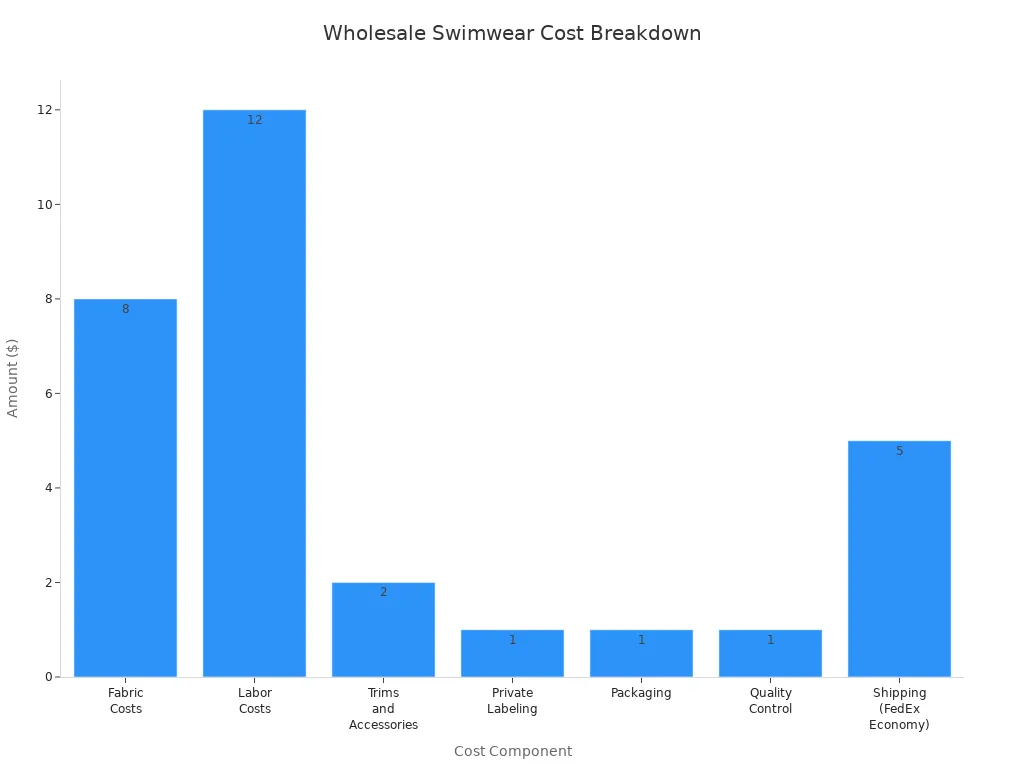

Componente di costo | Importo ($) |

|---|---|

Costi del tessuto | 8 |

Costi del lavoro | 12 |

Rifiniti e accessori | 2 |

Etichettatura privata | 1 |

Imballaggio | 1 |

Controllo di qualità | 1 |

Spedizione (FedEx Economy) | 5 |

30 |

Lavoro e produzione

Il lavoro è una parte importante del costo. Dove si trova il tuo produttore cambia i prezzi del lavoro. Ad esempio, gli Stati Uniti Le fabbriche possono caricare$10-$20 per pezzo. Le fabbriche di altri paesi possono addebitare$2-$5. Il costo del lavoro paga per cucire, tagliare e mettere insieme il tessuto. I bravi lavoratori fanno costumi da bagno migliori e meno errori. Vuoi che il tuo produttore controlli la qualità ad ogni passo.

Tasse di campionamento e di installazione

Prima di fare un sacco di costumi da bagno, si paga per i campioni e la configurazione. Queste tasse coprono il design, i pacchetti tecnologici e la realizzazione dei primi pezzi. I campioni costano da $100 a $300 ciascuno. Le commissioni di installazione possono arrivare fino a $500Per ogni stile. Questi costi ti aiutano a controllare l'idoneità e la qualità prima di ordinare molto. Il controllo della qualità durante il campionamento è importante per buoni risultati.

Branding e imballaggio

Il marchio personalizzato aiuta il tuo costume da bagno a distinguersi. Paghi per l'etichettatura privata, la stampa del logo e l'imballaggio speciale. Per 100 pezzi, il marchio e l'imballaggio possono costare circa $300. L'imballaggio ecologico e il marchio personalizzato rendono il tuo marchio un bell'aspetto e mostrano che ti importa del pianeta. Una buona confezione mantiene anche il tessuto sicuro e di alta qualità. Ogni dettaglio, dai tag alle scatole, aiuta a raccontare la storia del tuo marchio.

Costi di consegna

I costi di consegna dipendono da quanto è grande e pesante il tuo ordine. La spedizione in diversi paesi cambia il prezzo. Potresti pagare un extra per le scartoffie o la dogana. Se non pianifichi bene la spedizione,I costi possono salire del 20%. Il produttore ti aiuterà a scegliere la spedizione migliore per mantenere il tuo tessuto sicuro e di alta qualità.

Suggerimento: chiedi sempre al tuo produttore di costumi da bagno personalizzati per un completoRipartizione dei costi. Questo ti aiuta a vedere dove vanno i tuoi soldi e mantiene il tuo prezzo e la tua qualità equilibrati.

MOQ e il suo impatto sui prezzi all'ingrosso

Definizione e importanza della MOQ

Quando lavori con un produttore di costumi da bagno personalizzati, sentirai il termine moq molte volte. IlQuantità di ordine minimo, o moq, Significa il minor numero di costumi da bagno che devi ordinare per ogni stile o colore. I produttori impostano il moq per coprire i costi di installazione, manodopera e materiale. Se vuoi creare un nuovo design, il moq aiuta la fabbrica a gestire le sue risorse e mantenere la produzione efficiente.

ALow moq ti consente di testareNuovi stili o colori senza spendere troppi soldi. Questa opzione funziona bene per piccoli marchi o acquirenti per la prima volta. Alcuni produttori offrono un moq basso, come 12 bikini, che è perfetto se vuoi iniziare in piccolo. Altri impostano un alto moq, come 300 pezzi, per assicurarsi che coprano tutti i costi e offrano prezzi migliori per unità.

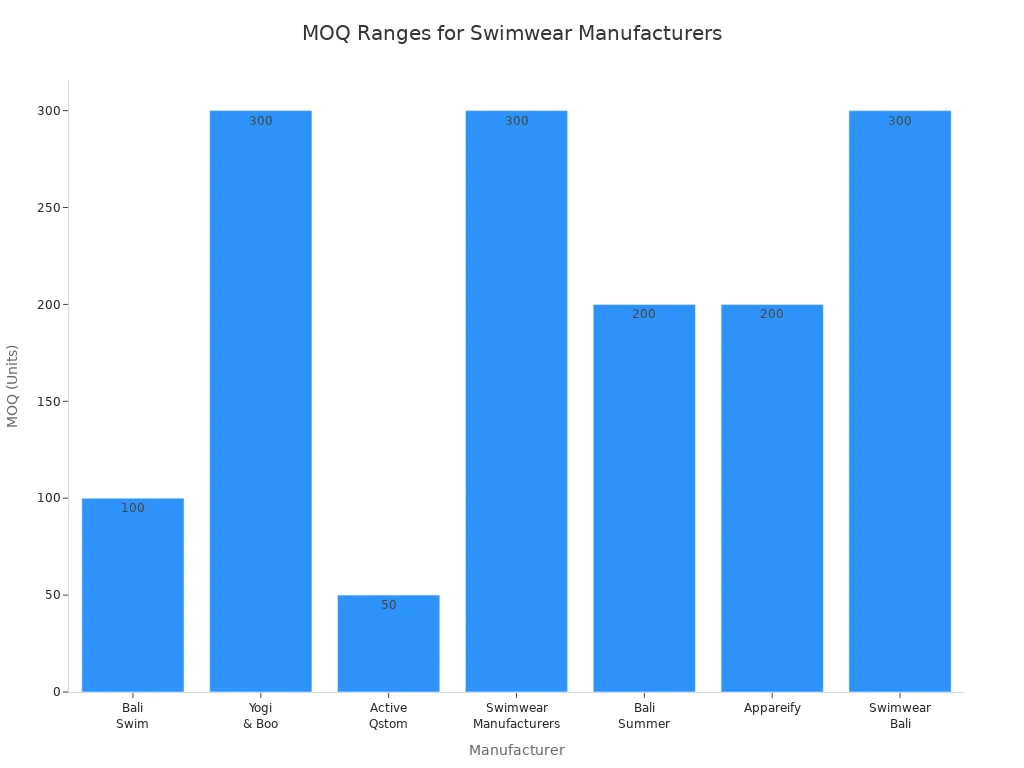

Ecco alcuniGamme moq tipiche per i produttori di costumi da bagno personalizzati:

Produttore | Gamma MOQ |

|---|---|

Bali Nuota | A partire da 100 |

Yogi & Boo | Intorno a 300 |

Qstom attivo | Inizia da 50 |

Costumi da bagno Produttori | Minimo di 300 |

Estate di Bali | A partire da 200 o $3.000 |

Appareify | Inizia a 200 |

Costumi da bagno Bali | A partire da 300 |

Fornitore Oro | Varia in base al fornitore |

12 bikini in totale: ottimo per i nuovi acquirenti.

80 bikini in totale (etichettatura privata): Ordine minimo per l'etichettatura privata.

120 bikini in totale (design personalizzato): punto di partenza per disegni personalizzati.

In che modo MOQ influisce sul prezzo unitario

Il moq che scegli cambia il prezzo che paghi per ogni costume da bagno. Quando ordini un moq basso, ilIl costo per unità aumenta. Ciò accade perché la fabbrica distribuisce i costi di installazione, manodopera e tessuto su un numero inferiore di articoli. Se scegli un alto moq, ottieni un prezzo inferiore per unità. La fabbrica può acquistare materiali alla rinfusa e lavorare in modo più efficiente, in modo da risparmiare denaro.

Un moq basso significa un prezzo più alto per costume da bagno.

Un alto moq significa un prezzo inferiore per costume da bagno.

Gli ordini all'ingrosso ti aiutano a ottenereSconti e offerte migliori.

Alcuni produttori offrono risparmi speciali per gli ordini all'ingrosso. Ad esempio,Bali Swim offre sconti progressiviMan mano che il tuo ordine cresce. Contrado offre il 20-40% di sconto sul prezzo base quando ordini di più. Printful offre fino al 17% di sconto se ordini almeno 25 articoli e puoi mescolare dimensioni e stampe.

Suggerimento: se vuoi mantenere il tuo prezzo basso, prova a soddisfare l'alto moq impostato dal tuo produttore. In questo modo, ottieni il miglior valore per la tua linea di costumi da bagno personalizzati.

Come calcolare i prezzi all'ingrosso

Metodi e formule di prezzo

Per capire i prezzi all'ingrosso, hai bisogno della formula giusta. Per prima cosa, aggiungi tutti i tuoi costi. Ciò significa tessuto, finiture, manodopera, imballaggio e consegna. Assicurati di non dimenticare alcun costo. Un produttore di costumi da bagno personalizzati controlla anche le tendenze generali e del mercato prima di scegliere un prezzo.

I produttori utilizzano modi diversi per fissare i prezzi all'ingrosso. Alcuni usano formule facili. Altri usano più passaggi per ottenere il prezzo. Ecco una tabella con formule comuni che potresti vedere:

Descrizione della formula | Formula | Esempio |

|---|---|---|

Calcolo del prezzo al dettaglio raccomandato | Prezzo all'ingrosso/ (1-Percentuale di markup) = Prezzo al dettaglio | $60 (prezzo al dettaglio) x (1-0, 55) = $27 (prezzo all'ingrosso) |

Calcolo del prezzo all'ingrosso di base | Costo delle merci x 2 | Assicura almeno il 50% di margine di profitto all'ingrosso |

Metodo dei prezzi Keystone | Prezzo al dettaglio/2 = Prezzo all'ingrosso | Se il prezzo al dettaglio è $60, allora il prezzo all'ingrosso = $30 |

Prezzi di assorbimento | Prezzo all'ingrosso = Prezzo di costo + Margine di profitto | Include tutti i costi associati e il margine di profitto desiderato |

Un calcolatore del prezzo all'ingrosso può aiutarti a controllare la tua matematica. La maggior parte dei marchi utilizza la formula di base. Questa formula raddoppia il tuo costo per ottenere un margine di profitto del 50%. Alcuni marchi usano il metodo keystone. Ciò significa che il prezzo all'ingrosso è la metà del prezzo al dettaglio. I prezzi di assorbimento ti consentono di aggiungere ogni costo e scegliere il tuo profitto.

Suggerimento: controlla sempre la tua formula prima di impostare i prezzi. Questo ti aiuta a mantenere alti i profitti e la qualità.

Pensa alle tendenze stagionali quando stabili i prezzi. Durante i periodi di punta, i produttori possono modificare i loro prezzi. Potrebbero dare prezzi più bassi per grandi ordini. Possono addebitare di più per la consegna veloce. Puoi risparmiare denaro se ordini all'ingrosso perché il costo per costume da bagno diminuisce.

Impostazione dei margini di profitto

Vuoi fare soldi con ogni costume da bagno che vendi. Per fare questo, è necessario scegliere il giusto margine di profitto. La maggior parte dei marchi sceglie tra il 30% e il 50%. Questo ti aiuta a coprire i costi e a far crescere la tua attività.

Ecco un modo semplice per impostare il prezzo e il profitto:

Scopri quanto costa fare un costume da bagno.

Scegli il tuo margine di profitto. La maggior parte dei marchi sceglie il 30%, il 40% o il 50%.

Usa questa formula:

Prezzo all'ingrosso = Costo di produzione/ (1-Margine di profitto)Ad esempio, se il tuo costo è di $10 e vuoi un profitto del 50%, usa questa formula:

Prezzo all'ingrosso = $10 / (1-0, 5) = $20Confronta il tuo prezzo con altri marchi per rimanere competitivo.

Puoi usare questa formula anche per impostare il tuo prezzo al dettaglio. Se vuoi un markup del 55%, usa questa formula:

Prezzo al dettaglio = Prezzo all'ingrosso/(1-0, 55)

Se il tuo prezzo all'ingrosso è $27, il tuo prezzo al dettaglio sarà di circa $60.

Nota: includere sempre ogni costo nella tua formula. Questo mantiene il tuo profitto sicuro e la tua qualità alta.

Un buon piano tariffario aiuta il tuo marchio a crescere. Puoi cambiare la tua formula se i tuoi costi vanno verso l'alto o verso il basso. Puoi anche offrire sconti per grandi ordini. Un produttore di costumi da bagno personalizzati può aiutarti a trovare il modo migliore perPrezzi stabilitiIn modo da mantenere il vostro profitto e la qualità forte.

Scelta di un produttore di costumi da bagno personalizzati

Confronto dei prezzi preventivi

Quando guardi le quotazioni dei prezzi, non scegliere solo quella più economica. Dovresti pensare sia al prezzo che alla qualità. Prova a trovare un buon mix di entrambi. UsoQuesta lista di controlloPer aiutarti a scegliere:

Assicurati che il produttore controlli spesso la qualità. Questo mantiene i tuoi costumi da bagno sempre uguali.

Chiedi quanto tempo ci vuole per effettuare il tuo ordine. Vuoi che il tuo costume da bagno venga consegnato in tempo.

Vedi se il produttore risparmia denaro senza abbassare la qualità.

Controlla se sono a conoscenza di nuovi stili di costumi da bagno. Le nuove idee sono importanti.

Assicurati che possano lavorare con tessuti elastici e cuciture forti.

Guarda le loro scelte di tessuto. I tessuti buoni ed ecologici sono migliori.

Vedi se puoi cambiare i disegni per soddisfare le tue esigenze.

Assicurati che il loro ordine minimo sia giusto per te.

Chiedi come controllano la qualità durante la produzione.

Scegli un produttore che parla chiaramente e ti aiuta in ogni fase.

Controlla quali servizi extra vengono con il prezzo. Alcuni produttori aiutano con la progettazione e controllare la qualità. Questi servizi ti aiutano a evitare erroriE mantieni i tuoi costumi da bagno belli. Anche se questi costano di più, aiutano il tuo marchio a crescere e ti danno più valore.

Suggerimento: chiedi sempre campioni prima di ordinare. Leggi le recensioni e controlla la velocità con cui terminano gli ordini prima di scegliere un produttore.

Suggerimenti per la negoziazione

Puoi risparmiare denaro utilizzandoModi intelligenti per parlare con i produttori. Ecco alcuni suggerimenti per aiutarti:

Strategia | Descrizione |

|---|---|

Comprensione dei tassi di mercato | Scopri quali prezzi sono normali in questo momento. |

Sfruttare il volume per gli sconti | Ordina più pezzi per ottenere prezzi più bassi. |

Discutere dei termini di pagamento | Richiedi piani di pagamento che ti aiutino a pagare più facilmente. |

Costruire relazioni forti | Lavora bene con il tuo produttore per offerte migliori in seguito. |

Quando parli di moq o chiedi prezzi più bassi, sii onesto e chiaro. I produttori possono permetterti di ordinare in bundle o offrire condizioni migliori. Inizia con un piccolo ordine per costruire la fiducia. Questo può aiutarti a ottenere offerte migliori la prossima volta. Ricorda, hai bisogno sia di buoni prezzi che di buona qualità per far bene la tua azienda.

Scopri i prezzi all'ingrosso aggiungendo tutti i costi insieme. Ciò significa che conti i costi di tessuto, manodopera e consegna. Quando conosci ogni costo, puoi fare scelte migliori. Puoi ancheImposta buoni margini di profitto per i tuoi costumi da bagno. Imparare a conoscere MOQ ti aiuta a mantenere i costi bassi e la qualità alta. Queste informazioni ti aiutano a parlare con i produttori e a trovare costi nascosti. Puoi impostare prezzi che aiutano il tuo marchio a rimanere forte e fare soldi.

FAQ

Qual è il costo più importante nella produzione di costumi da bagno personalizzati?

Il tessuto di solito costituisce la maggior parte del tuo costo. I tessuti di alta qualità o ecologici costano di più. Dovresti sempre chiedere al tuo produttore le opzioni e i prezzi del tessuto.

Puoi abbassare il prezzo all'ingrosso aumentando la dimensione dell'ordine?

Sì! Quando ordini più pezzi, il prezzo per costume da bagno scende. I produttori danno sconti per gli ordini all'ingrosso. Risparmi denaro soddisfacendo o superando la quantità minima di ordine.

Come fai a sapere se la citazione di un produttore è giusta?

Confronta le citazioni di almeno tre produttori. Controlla cosa include ogni prezzo, come tessuto, finiture e spedizione. Chiedi una ripartizione completa dei costi. Questo ti aiuta a vedere se ottieni un buon valore.

Devi pagare per i campioni ogni volta?

Di solito si paga per i campioni, soprattutto per i nuovi disegni. Alcuni produttori possono offrire campioni gratuiti se si effettua un grande ordine in seguito. Chiedi sempre informazioni sulle tariffe del campione prima di iniziare.